Standard external installation pipe cutting and beveling machine

Product Description

Shenrui Standard External Installation Pipe Cutting and Beveling Machine, with a processing range set according to international pipeline standards, can perform single cutting or single bevel processing on various specifications of pipelines, containers, and flanges. It can also complete cutting bevel processing simultaneously, and can also perform composite bevel and flange surface processing. Its design is clever, installation and operation are very simple, and the body is a split ring structure, making disassembly and assembly very convenient, It can be installed at any position on pipelines and is a movable pipeline cutting and beveling machine tool. It is suitable for cutting and beveling various grades of metal materials such as carbon steel, stainless steel, alloy steel, and special hard engineering materials. It is widely used in pipeline installation projects and on-site pipeline repair operations in industries such as petroleum, chemical, natural gas, food, boilers, pharmaceuticals, nuclear power, and venue construction.

Product features

1. The diameter span of a single machine is 6 inches;

2. 16 specifications, capable of processing pipe diameters of 20-1240mm;

3. One clamping, cutting and beveling simultaneously;

4. Complete cold cutting method without changing the material of the pipe;

5. Automatic feed, no need for manual adjustment, high efficiency, high quality;

6. Hinged split body, installed in sections at any position on the pipeline;

7. The fixed ring is made of aluminum alloy or alloy steel, and the moving ring is made of alloy steel;

8. More processing accessories are available for improving performance and expanding processing capabilities;

9. Optional driving methods: electric, pneumatic, CNC, hydraulic;

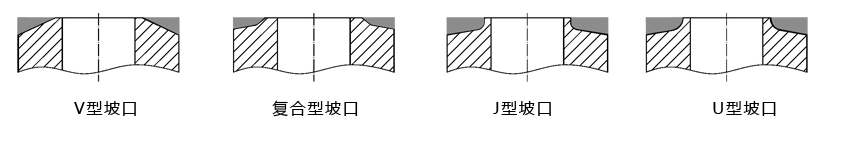

10. Machinable cutting groove forms: U-shaped, V-shaped, J-shaped, as well as double V-shaped and composite types;

11. The installation methods of the drive head include direct connection and direct intersection, to avoid interference and meet the requirements for optimal installation position;

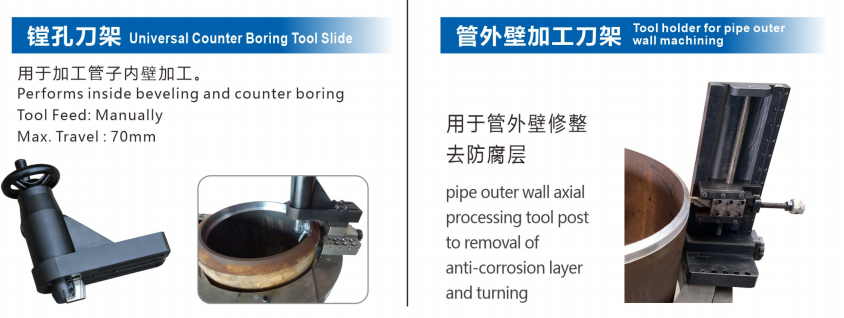

Processing function

1. Pipeline cutting; 2. Internal and external slope openings at pipe ends; 3. Flat end of pipe; 4. Simultaneously cutting off the groove; 5. Composite groove; 6. Boring inner holes; 7. Repair of the outer wall of the pipe; 8. Processing flange surface; 9. Car groove

Machinable cutting groove forms: U-shaped, V-shaped, J-shaped, as well as double V-shaped and composite types

|

规格型号 |

加工范围 |

最大壁厚mm |

刀盘转速 |

|||||

|

电动式 |

气动式 |

数控式 |

液压式 |

mm |

inch |

单刀 |

叠刀 |

rpm |

|

ISD-90 |

ISF-90 |

SKD-90 |

HYD-90 |

Ф20~90 |

3/8"-3" |

30 |

- |

34 |

|

ISD-168 |

ISF-168 |

SKD-168 |

HYD-168 |

Ф25~168 |

1"~6" |

30 |

50 |

24 |

|

ISD-219 |

ISF-219 |

SKD-219 |

HYD-219 |

Ф50~219 |

2"~8" |

30 |

50 |

23 |

|

ISD-273 |

ISF-273 |

SKD-273 |

HYD-273 |

Ф114~273 |

4"~10" |

30 |

75 |

23 |

|

ISD-323 |

ISF-323 |

SKD-323 |

HYD-323 |

Ф168~323 |

6"~12" |

30 |

75 |

23 |

|

ISD-355 |

ISF-355 |

SKD-355 |

HYD-355 |

Ф177~355 |

8"~14" |

30 |

110 |

23 |

|

ISD-406 |

ISF-406 |

SKD-406 |

HYD-406 |

Ф254~406 |

10"~16" |

30 |

110 |

22 |

|

ISD-457 |

ISF-457 |

SKD-457 |

HYD-457 |

Ф323~457 |

12"~18" |

30 |

110 |

20 |

|

ISD-508 |

ISF-508 |

SKD-508 |

HYD-508 |

Ф355~508 |

14"~20" |

30 |

110 |

20 |

|

ISD-559 |

ISF-559 |

SKD-559 |

HYD-559 |

Ф406~559 |

16"~22" |

30 |

110 |

14 |

|

ISD-610 |

ISF-610 |

SKD-610 |

HYD-610 |

Ф457~610 |

18"~24" |

30 |

110 |

14 |

|

ISD-762 |

ISF-762 |

SKD-762 |

HYD-762 |

Ф610~762 |

24"~30" |

30 |

110 |

13 |

|

ISD-914 |

ISF-914 |

SKD-914 |

HYD-914 |

Ф762~914 |

30"~36" |

30 |

110 |

11 |

|

ISD-1066 |

ISF-1066 |

SKD-1066 |

HYD-1066 |

Ф914~1066 |

36"~42" |

30 |

110 |

10 |

|

ISD-1160 |

ISF-1160 |

SKD-1160 |

HYD-1160 |

Ф980~1160 |

38"~44" |

30 |

110 |

9 |

|

ISD-1240 |

ISF-1240 |

SKD-1240 |

HYD-1240 |

Ф1040~1240 |

40"~48" |

30 |

110 |

9 |

Driving method

|

The relevant technical parameters are for reference only and do not serve as the final delivery standard

|

|